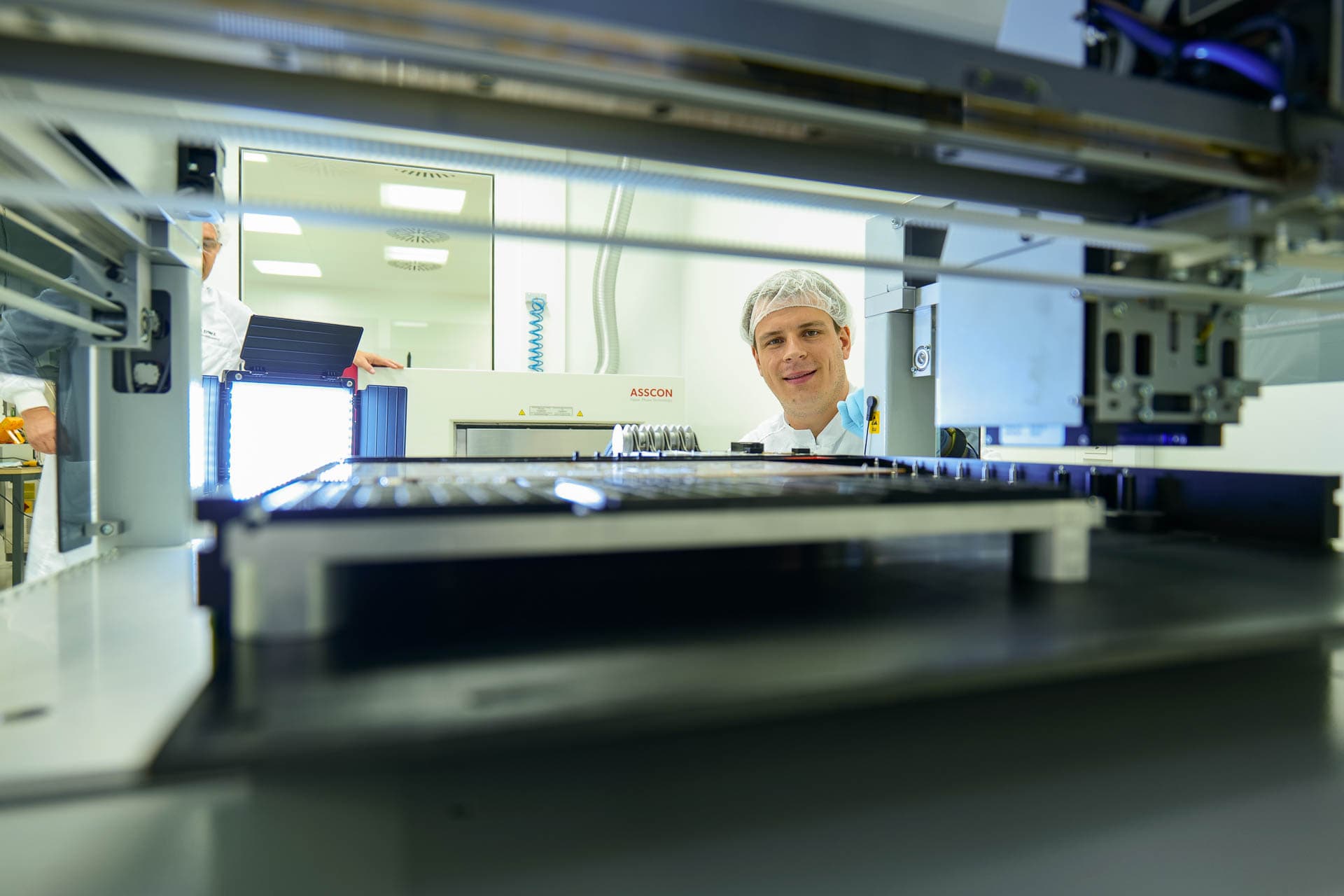

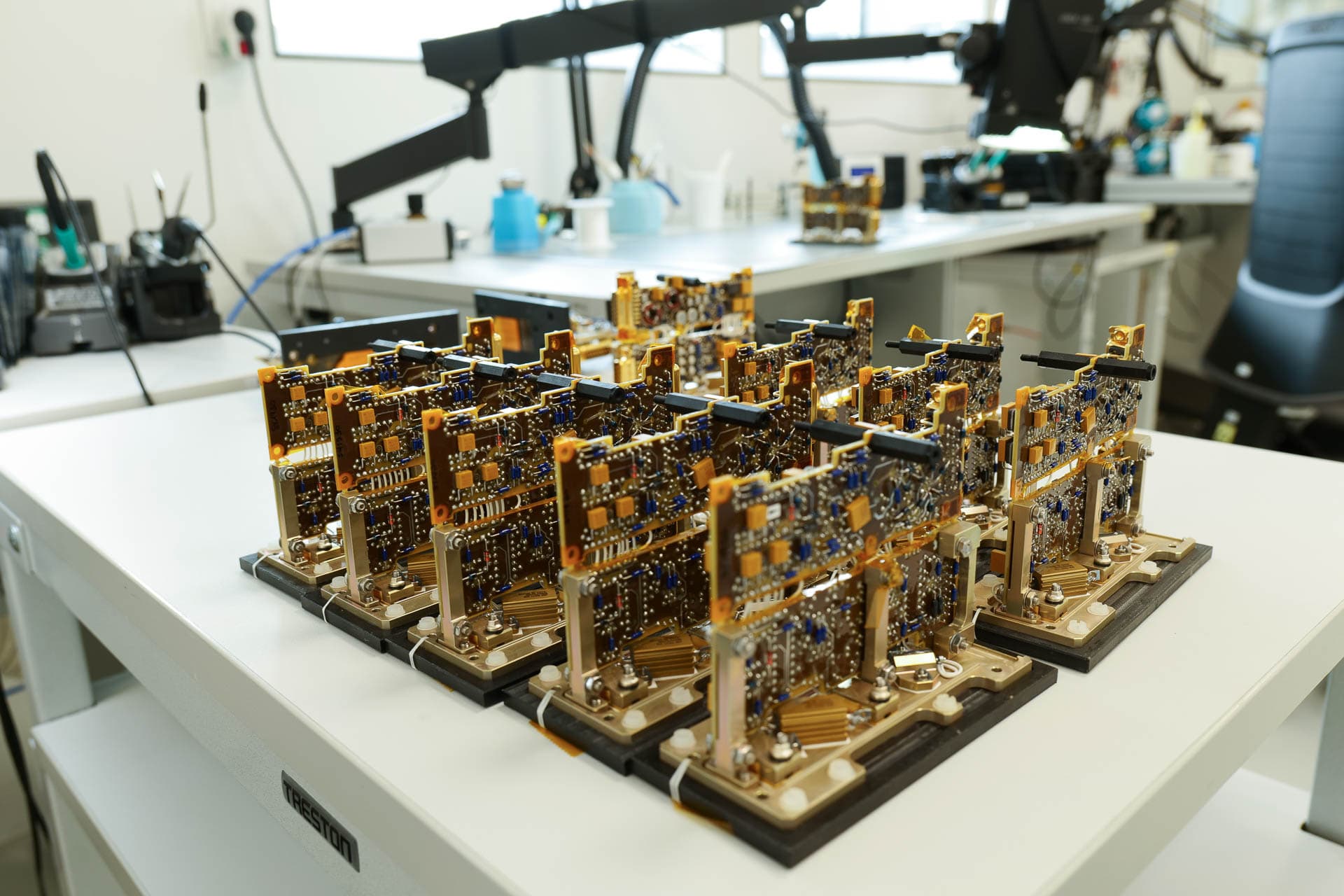

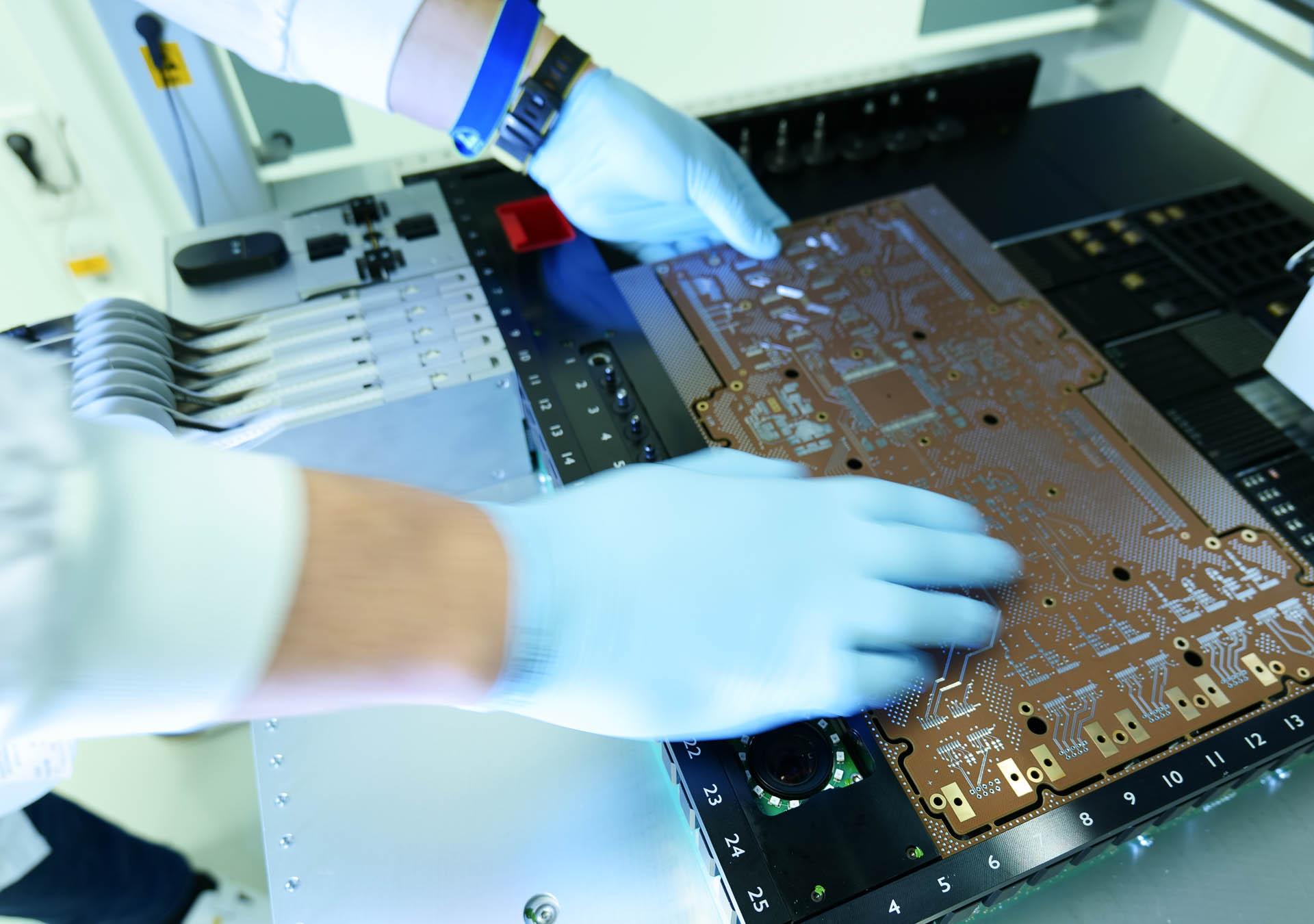

SMD und THT assembly

Manufacturing printed circuit boards (PCBs) according to ESA standards is our key competence. For this reason, our manufacturing team trains their craft in special courses and at regular intervals using the high criteria of the ESA. We employ each of our highly qualified manufacturing employees for flight hardware directly and with long-term perspective in our company.

ASP features about 700m² clean room area of ISO class 8, distributed between the ASP headquarters “Am Wasserstall 2” and the ASP manufacturing site “In Oberwiesen 16”. This allows us to implement a redundant manufacturing concept.

- Our SMT manufacturing processes are approved by ESA through document GP 11214-1000 ASP/01, Issue 8.

- Document ESA-TECQTM-LE-1799, Issue 5 lists all SMD package types qualified by ASP for vapor phase and hand soldering

The process steps in detail are

- Incoming goods inspection and microsection inspection

- Automatic placement of SMD components

- Vapor phase soldering of SMD components

- Manual soldering of wired components

- Cleaning of parts and assemblies

- Conformal coating

- Mechanical and electrical integration

Applied standards

- ECSS-Q-ST-70-08C:

Manual Soldering of High-Reliability Electrical Connections - ECSS-Q-ST-70-38C:

High Reliability Soldering of SMD components (manual and vapourphase) - ECSS-Q-ST-70-28C:

Repair and Modification of PCB Assemblies for space use - ECSS-Q-ST-70-26/30C:

Crimp process

ASP-ServiceSMD und THT assemblyOur offer to you

ASP offers electronics manufacturing according to ESA standards as a service to interested companies.